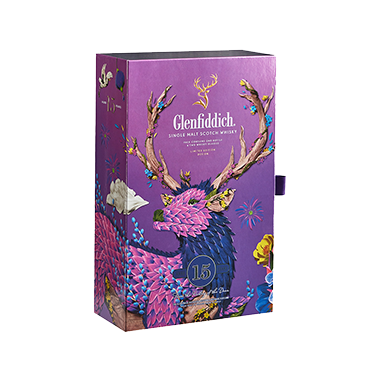

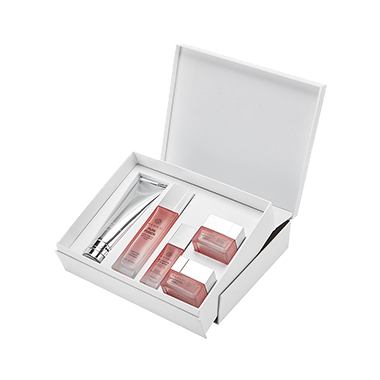

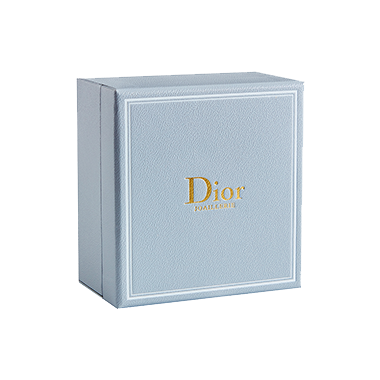

Trusted Luxury Packaging Manufacturer

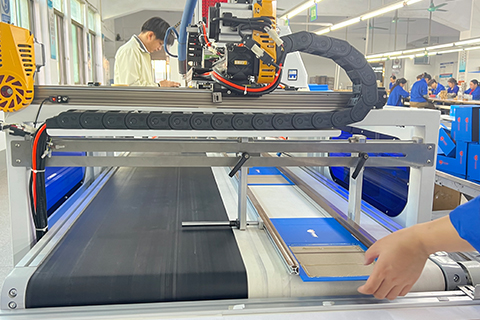

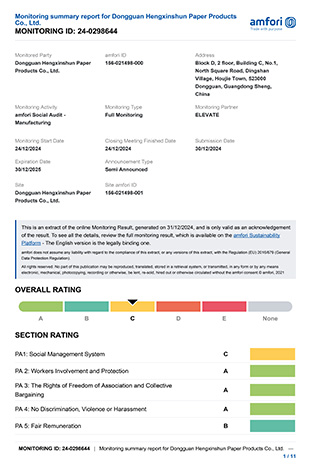

Dongguan Donghong Paper Products Co., Ltd. is a professional manufacturer of various types of gift boxes, paper boxes, packaging boxes, rigid boxes, magnetic boxes. Covering an area of 10,000 square meters, with 206 skilled workers, digital pre-press devices and automatic post-press facilities, our company is well equipped.

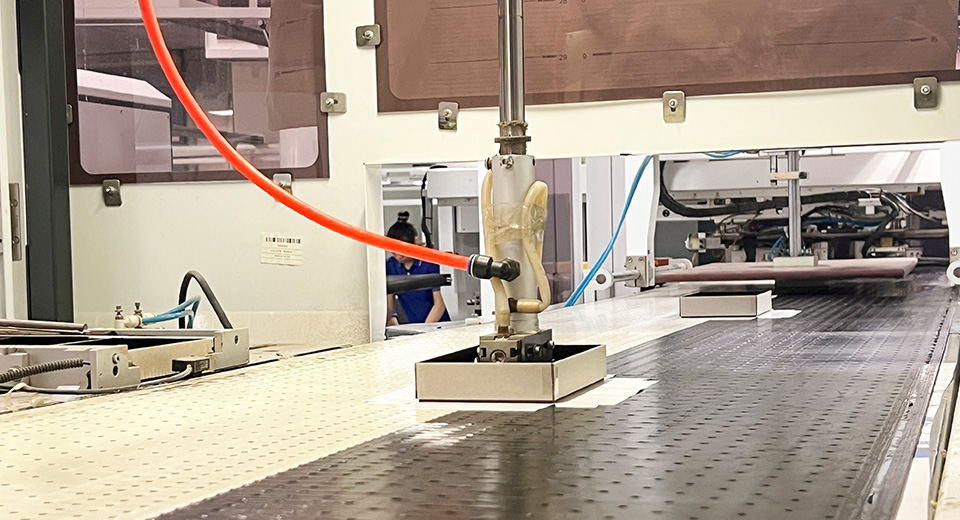

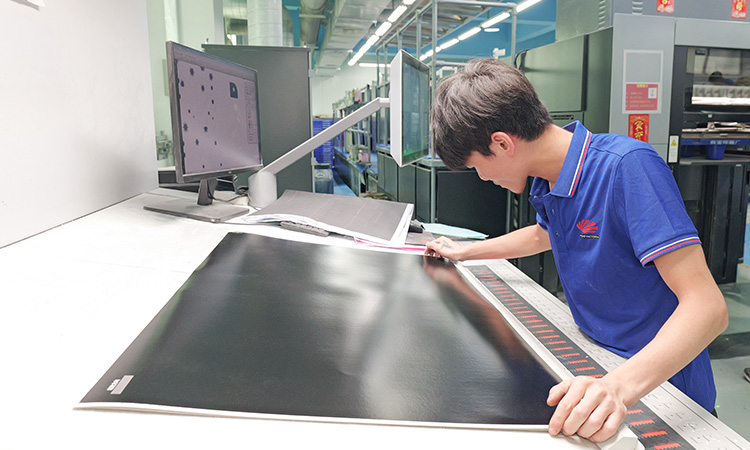

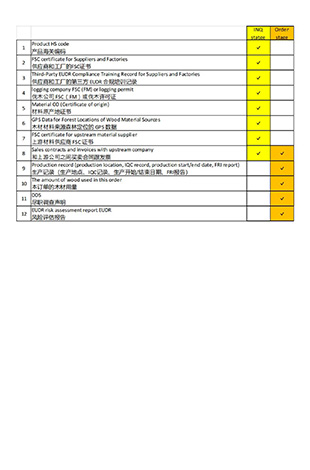

As a responsible and credible factory, caring about integrity, with a well-established quality management system and an environment-friendly production system, Dongguan Donghong Paper Products Co., Ltd. has obtained respect and trust from costumers. Be a Printer, Be an Expert. Our factory is equipped with UV printing machines, automatic die-cutting machines, omnipotence folding paper machines and automatic glue-binding machines. Moreover, the continuous improvement of scientific management and enhancement of quality control procedures have enabled us to effectively maximize customers' values by fulfilling their specifications in a positive manner.