The Ultimate Guide to UV Printing in Packaging Boxes

Quote: DHPBOXES high-end packaging box engineering guide

UV printing technology is a revolutionary printing method, which is suitable for producing high-end packaging boxes, especially for wine bottles, perfume boxes, jewelry boxes and other luxury goods packaging areas. Its unique color appearance and durability make it an excellent choice for high quality products. In this issue, DHP BOXES will take you through the advantages, efficiency, and essential process combinations of UV printing.

1.What is UV printing?

UV printing is a printing technology that uses ultraviolet light to instantly harden oil ink. The light content in the ink is removed, and after irradiation with the UV lamp, the liquid is immediately removed and the liquid is removed, and the oil is left to dry naturally.

This meaning:

• Colorful color: ink remains on the surface, non-covered paper absorbs

• Advice: Matching product LOGO, text, fine lines

• Abrasion resistance: After hardening, the ink layer is hardened.

• Suitable for various materials: various types of paper, suitable for plastics, metals, strength, glass, etc.

The quality of the brand is high-end, and UV printing is a must-have technology for quality.

2. Comparison with Traditional Printing Processes

Traditional printing often uses solvent-based or water-based inks, relying on evaporation or absorption for drying. Due to the long drying time, problems such as ink sticking, adhesion, and color diffusion are common. In contrast, UV printing:

• Offers instant curing, eliminating the need for lengthy drying times.

• The ink layer is not absorbed by the paper, resulting in more vibrant colors and smoother edges.

• Applicable to a wider range of substrates (not limited to cardboard, but also plastics, metals, acrylic, glass, etc.) – particularly advantageous for packaging boxes.

For DHPBOXES, adopting UV technology in high-end packaging boxes significantly enhances brand visual appeal and texture, thereby strengthening the competitiveness of their products in the European and American markets.

3. The core application effects of UV printing in high-end packaging

A. Superior Color and Detail Representation

• High color saturation and natural transitions

• Sharp pattern edges

• Suitable for printing small text, sophisticated textures, and logo graphics

B. Advanced Surface Effects

• Spot UV

• High-gloss UV

• Matte and gloss contrast

• 3D tactile UV (thick coating UV)

These effects significantly enhance the visual appeal of luxury brands.

C. Versatility of Application

UV printing can be applied to a variety of substrates. This flexibility allows various types of packaging boxes to maintain high quality while creating a unified brand image across product lines.

D. Environmental Advantages

• UV is a low-VOC process, complying with European and American environmental regulations

• Suitable for environmentally friendly paper materials and sustainable packaging trends

4. Common UV process combinations in the high-end packaging industry (must read)

(1) UV + hot stamping (Gold / Silver / Rose Gold / Laser)

Suitable for: High-end wine boxes, perfume boxes, jewelry boxes, and holiday gift boxes

Advantages:

• Highly contrasting gloss, extremely eye-catching

• Enhanced logo presentation

• Colors and UV coatings can create a multi-layered light effect

(2) UV + Emboss / Deboss

Advantages:

• Combines visual and tactile experiences

• Better suited for minimalist brands (only logo, low lighting)

• Enhances the structural feel of the box surface

(3) UV + Soft-touch Lamination

This is a common combination in luxury goods, featuring a striking contrast between gloss and texture.

Advantages:

• Matte velvet background

• Glossy UV logo for a striking visual impact

• Significantly improved scratch resistance

Suitable colors:

• Black, burgundy, dark green, deep blue

(4) UV + Matte Lamination

Features:

• More understated than skin-feeling masks

• Gives a "high-end minimalist" visual impression

Suitable industries:

• Beauty and skincare

• High-end electronics

• Essential oil gift sets

(5) Special UVs

Both laser UV printing and reverse UV printing offer a metallic and futuristic look.

Suitable for electronic products, dental cases, etc.

5.Recommended Paper Materials and Structures for UV Processing

1. Suitable Paper Materials for UV Processing (High Stability)

• Coated Paper (Highly Recommended)

• Specialty Papers (Leather Texture, Beaded Texture, Metallic Paper)

• Black Cardstock

• Pearlescent Paper

• Gold and Silver Cardstock

• Outer Laminating Paper for Gray Board

2. Paper Materials Requiring Testing

(From Uploaded Document)

• Fabric Texture Paper, Linen Texture Paper with Deep Texture

• Highly Absorbent Environmentally Friendly Paper

• Rough Kraft Paper

Suggestions:

✔ Proof UV Intensity

✔ Verify Pantone Color Numbers

6.Packaging Box Structures Best Suited for UV Printing

(1) Rigid Lid & Base Box

Large UV display area, suitable for textures, gradients, and patterns.

(2) Magnetic Flip-Top Box (Book-Style Box)

Excellent UV effect for the logo on the surface; can be achieved with a skin-like film for a "high-end black" finish.

(3) Drawer Box

Textured UV finish on the outer cover; hot stamping + UV combination on the drawer front.

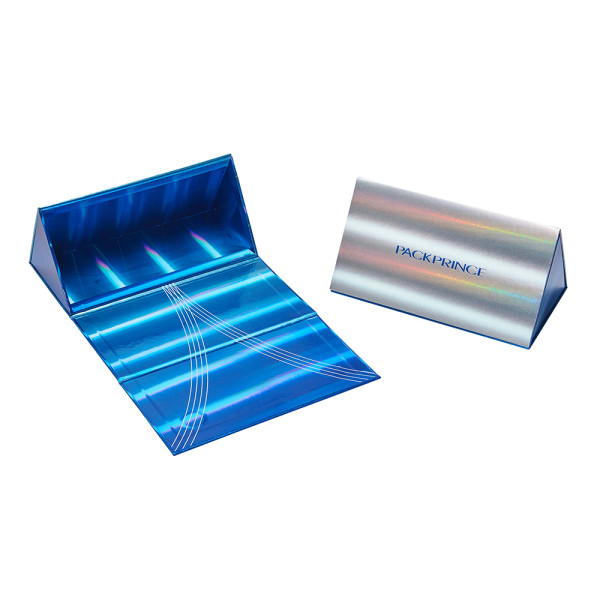

(4) Double Door Box

UV printing on the inner door panels enhances the unboxing experience.

7.Common UV Printing Problems and Solutions (Professional Guidance)

This content is from your uploaded document, which I have reorganized into a more readable and professional structure.

Problem 1: Ink Bubbling/Falling

Causes: Paper absorbs moisture, surface contains oil, insufficient curing

Solutions:

• Ensure paper is dry and dust-free

• Increase UV intensity

• Special paper materials require pretreatment

Problem 2: Large Color Difference/Blurred Pattern

Causes: Uneven ink absorption in textured paper, Pantone not calibrated

Solutions:

• Proofing and color calibration

• Use a UV-compatible ink

Problem 3: Scratches/Poor Durability

Causes: Incomplete UV curing or ink too thin

Solutions:

• Apply a lamination (matte/gloss)

• Apply UV curing before hot stamping or embossing

8. DHPBOXES Case Studies

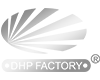

Custom Eco-friendly Aligner Case Packaging From DHP Factory | Lid And Base Box | Protectful Eva Foam Insert

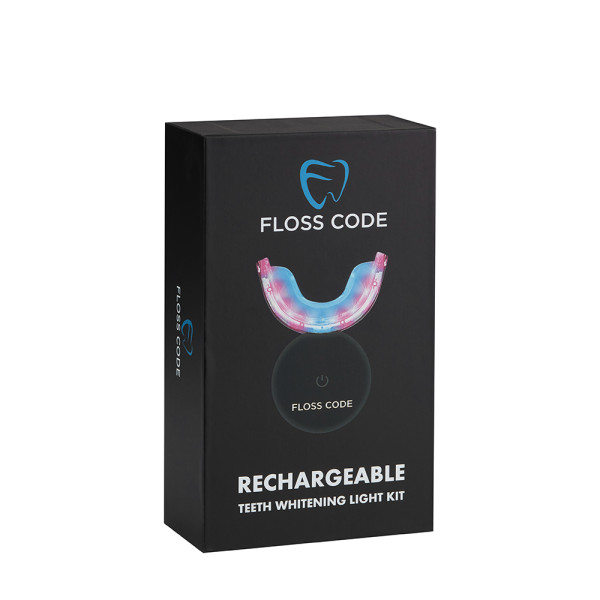

Custom Apparel Boxes With Logo | High Quality Magnetic Box Can Foldable | With Double Sides Adhesive Tape

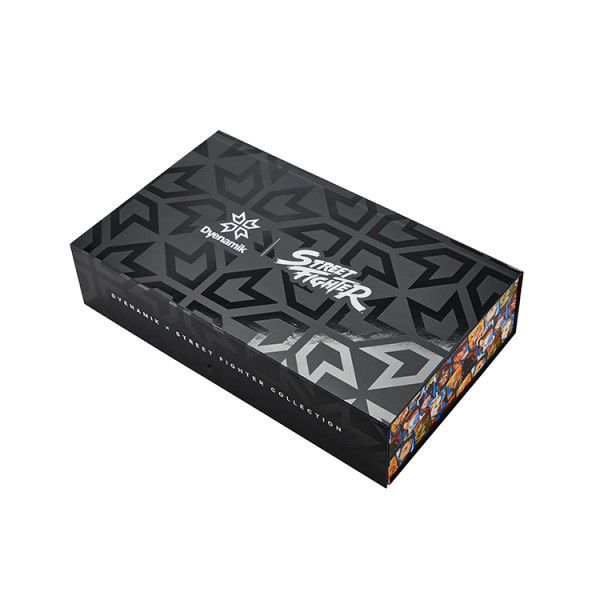

Discover our custom luxury watch boxes, made with eco-friendly materials and designed to fit your brand's needs. With PU leather linings and pillow, our watch boxes offer premium protection and style.

Custom Triangle Shaped Packaging Box for Clothing Brand | Rigid Cardboard Material

9. Conclusion

UV printing has become a core technology for enhancing the grade, texture, and durability of packaging. It not only determines whether packaging is "attractive," but also whether a brand can stand out on store shelves, in short videos, and in e-commerce photos.

For high-end brands serving the European and American markets:

UV is a value-added feature; it's about brand image.

DHPBOXES boasts a mature team and advanced equipment, providing brands with integrated solutions from structural design to UV process implementation.