The Ultimate Guide to Custom Cigarette Packaging

Note: Some tobacco markets have mandatory requirements for **health warnings, ingredient information, and standardized/plain packaging**, and regulations vary significantly from country to country. This article provides a general methodology from a packaging manufacturing and design perspective; for specific compliance requirements, please refer to the regulations of your target market and consult with legal counsel.

1) What is a "cigarette packaging template/die-cut drawing"? Why should customization start with it?

In tobacco packaging development, a "packaging template" is closer to what you commonly call a dieline: it's a "flat, unfolded structural blueprint" that marks cutting lines, creasing lines, gluing areas, bleed areas, hot stamping/UV coating, and other process zones. Its value lies in connecting "aesthetics" with "mass production"—ensuring that the design remains dimensionally accurate, aligned, and batch-stable after printing, die-cutting, folding, and box gluing.

Especially crucial for startups:

Less detours: Clearly defining the structure and printing rules from the start reduces repeated sampling costs.

Shorter cycle: Standardized templates allow for much faster new product launches/revisions.

Risk control: Reserving regulatory information areas in the template stage avoids major revisions later.

2) In-depth Analysis: How Much Branding Allows in Your Target Market?

Many countries/regions have strict restrictions on brand presentation space on tobacco packaging. Common mandatory requirements include:

Percentage of health warning area on both sides (many markets require large areas or even graphic warnings)

Prohibition of misleading descriptions and exaggerated claims

Standardized/plain packaging: Stricter rules regarding color, font, and element placement

These requirements align with Article 11 (Packaging and Labelling) of the Framework Convention on Tobacco Control (FCTC): emphasizing prominent health warnings, avoiding misleading information, and presenting information in the native language.

✅ Practical Suggestions (3 Steps Before Filing a Lawsuit)

List the countries/states of sale (or distribution channels)

Create mandatory regulatory information into "fixed information modules" (warnings/images, ingredients, traceability codes/tax stamp locations, etc.)

Review both structure and layout simultaneously: prioritize "compliance and feasibility" before considering "sophistication."

3) Common Cigarette Packaging Sizes and Structures

The most common type on the market is the 20-cigarette flip-top hard pack. Many supply chain sources give an outer diameter of approximately 85 × 55 × 22 mm (slight variations may occur between different countries and brands, and also for slim cigarettes, 100s, and soft packs).

A. How to Choose the Structure Type(Driving Back from "Selling Points")

Flip-top: Classic, highly recognizable on store shelves, suitable for most market segments.

Soft pack: Relatively cost-effective, soft to the touch, but less pressure-resistant.

Drawer/Sleeve: More "gift-oriented," suitable for limited editions/collaboration products.

Rigid gift box: Used for high-end series/gift sets (such as those with lighters, smoking accessories, etc.), offering the highest quality but at a higher cost.

4) Materials and Craftsmanship of Cigarette Packaging Boxes:

4.1 Common Material Combinations(Outer Box/Inner Lining)

Outer Box Cardboard: Primarily made of cardboard with good printability and sufficient stiffness (specific weight/thickness depends on structure and transportation requirements).

Inner Lining: Commonly used are aluminum foil composite linings or paper linings (used for barrier and aroma retention), selected according to brand and regulatory requirements.

4.2 Craftsmanship Selection

(Premium Feel ≠ More Craftsmanship is Better)

Brand feel is recommended to follow "1 main visual craftsmanship + 1 tactile enhancement + 1 detail":

Main Visual: Hot stamping (gold/silver), spot color (Pantone), large-area spot UV coating

Tactile Feel: Matte/velvet film (soft-touch)

Details: Embossing/deboss, miniature texture, fine line hot stamping

5) Design Files and Template Selection

5.1 Essential Technical Points for Dieline Design

Bleed: Typically at least 3mm (adjustable depending on the factory and equipment)

Safe Area: Keep critical information away from cut/fold lines

Line Type Specifications: Clearly define layers for cut lines, crease lines, window lines, hot stamping plates, and UV plates

Color Management: Clearly label CMYK/spot colors; devise strategies in advance to avoid color variations/color differences in large areas of black

Font Processing: Convert fonts to outlines or package them before delivery to avoid missing characters

5.2 Proofing Recommendations

White Proof (Structure Verification) → Digital Proof (Color/Layout) → Machine Proof (Critical Process Verification) Breaking down the "variables" for verification significantly reduces the probability of rework.

6) Sustainability and Environmental Protection:

Tobacco Packaging is Also Undergoing "Green Audits"

Many brands are asked about paper origin, coatings and adhesives, recyclability, and compliance certificates when exporting or entering more stringent markets. DHP BOXES' manufacturing and service page mentions its production capacity, processes (including dieline/sampling/printing/post-production/quality inspection), and related certifications and quality control systems, which are crucial for "deliverable and traceable" packaging projects.

7) Why consider DHP BOXES as one of your "leading supplier options"?

When you're making custom tobacco packaging, the real challenge isn't "drawing the design," but rather achieving stable mass production, on-time delivery, and keeping risks (color difference/alignment/process yield) within a predictable range.

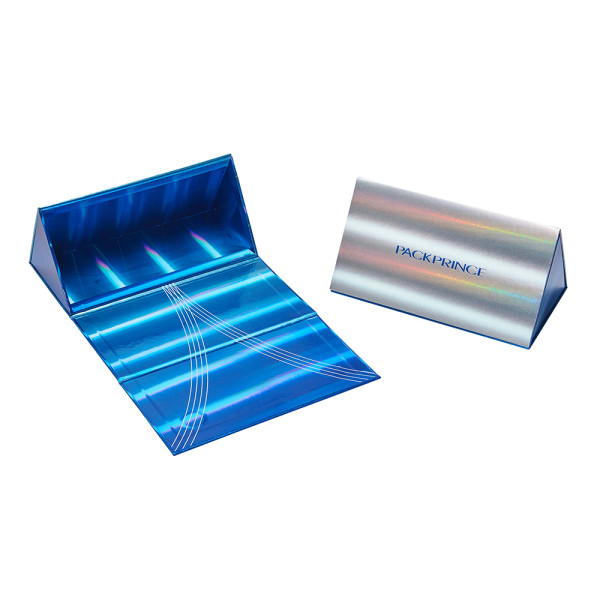

Custom Triangle Shaped Packaging Box for Clothing Brand | Rigid Cardboard Material

Premium custom whisky box with unique button, support eco-friendly materials and full customization by DHP Factory.

Custom Christmas Present Boxes with Lids | Christmas Festive Gift Packaging Boxes with PU Handle | Good Gift Box Options

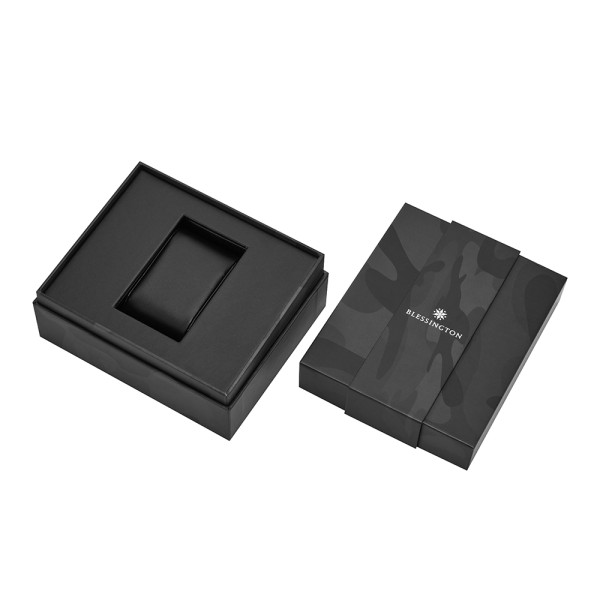

Discover our custom luxury watch boxes, made with eco-friendly materials and designed to fit your brand's needs. With PU leather linings and pillow, our watch boxes offer premium protection and style.

8) FAQ: 5 Most Frequently Asked Questions about Custom Cigarette Packaging

Q1: I only have one idea, can I do it without a structural drawing?

Yes. Make a white sample first to get the structure working, then proceed with design and manufacturing.

Q2: How is the MOQ determined?

It's strongly related to the structure, printing method, and process complexity. We suggest you first determine whether "spot color/hot foil/UV coating is required," as this will make negotiating the MOQ and unit price easier.

Q3: How long does it take to make a sample?

Commonly, a white sample/digital sample is made first, then a manufacturing sample; your official website service page also mentions the sample delivery cycle range, which can be assessed based on the complexity of the project.

Q4: How is color difference controlled?

The key lies in: color standards (Pantone/sample approval), paper batch, consistency between ink and printing parameters, and process inspection.

Q5: If the target market is standardized/plain packaging, can brand differentiation still be achieved?

In most cases, differences can only be made in structural experience, tactile feel, opening feel, material details, and details permitted by compliance; the regulatory boundaries must be clearly defined first.

Conclusion: Treating "standards" as part of the design process leads to faster and more stable customization.

The correct path for custom cigarette packaging is: Regulatory Boundaries → Structural Templates → Materials and Processes → Prototyping and Verification → Mass Production Quality Control.

As long as the process runs smoothly, even startup brands can create "distinctive, mass-producible, and consistently delivered" packaging within a controllable budget.