Industry Secrets: Why does embossing make packaging boxes more valuable?

Introduction: Why does embossing make packaging boxes more valuable?

In the high-end packaging sector, only when both visual appeal and tactile experience are outstanding can a brand's prestige and quality be truly conveyed. As a B2B customized packaging expert, DHPBOXES deeply understands the power of "first touch" and "first impression."

This article will focus on a highly expressive post-processing technique—Embossing—exploring why it is particularly crucial for luxury packaging boxes and showcasing the specific role of embossing in wine gift boxes, jewelry and watch packaging boxes, cosmetic boxes, and more.

What is Embossing?

A.Embossing refers to placing paper, specialty paper, or cardboard between a male die and a female die, applying pressure to create raised patterns, text, or textures on the material's surface.

B.This is contrasted with debossing—which involves pressing in rather than raising.

In packaging manufacturing, embossing is not only a visual decoration but also a tactile language—allowing consumers to experience the brand through their hands.

The Impact of Embossing on Packaging Boxes

1. Enhanced Brand Recognition and Visual Impact

Embossing allows brand logos, slogans, or key textures to stand out on the packaging surface, creating an interaction of light and shadow with texture, thus enhancing visual impact.

For wine gift boxes and jewelry boxes, a simple gesture or touch conveys a brand attitude of "high-end," "meticulous craftsmanship," and "uniqueness."

2. Improved Tactile Experience and a Premium Feel

Embossing transforms packaging from simply "looking" to "looking and touching." Enhanced tactile experience effectively increases the user's perceived value of the product.

In the context of DHPBOXES serving European and American luxury brands, this "tactile enhancement" is particularly crucial.

3. Differentiation and Brand Positioning

In the highly competitive gift packaging market, flat printing alone is no longer sufficient to stand out. Embossing, as a craft detail, can become part of a brand's differentiated identity. The article mentions using embossing to "make product packaging stand out and help customers remember your brand."

For wine packaging boxes, this detail particularly conveys a sense of luxury and customized professionalism.

4. Enhanced Tactile Feel and Practical Functionality

Beyond aesthetics, embossing improves the tactile feel of the box surface, such as reducing slippage or enhancing the opening experience. For luxury wine boxes with hinged lids or double doors, a stable opening and closing mechanism and grip are crucial.

5. Compatibility with Environmental Trends and Recyclable Materials

Embossing is an environmentally friendly process. Some embossing techniques maintain the material's recyclability by shaping the paper instead of adding ink, foil, or special coatings.

DHPBOXES leverages the advantages of environmentally friendly materials, replacing excessive printing or metallic lamination with embossing, which not only enhances the texture but also meets the sustainable packaging requirements of European and American customers.

Common embossing techniques and their applica tions in packaging boxes

Heat Embossing

Typically used for handmade cards or small-batch printing projects; however, its application is relatively rare in large-scale cardboard packaging due to consistency and production capacity limitations. If the budget allows, using this process for limited-edition wine boxes or gift boxes can serve as a "masterpiece" design.

Dry Embossing

Achieved through embossing and debossing using molds and presses, this process eliminates the need for heated powder, making it more suitable for industrial packaging production. DHPBOXES utilizes this process to provide clear, high-quality embossing for wine boxes, chocolate boxes, and more.

Foil Embossing

Combining embossing with metallic foil creates a stronger raised effect and a more dazzling visual impact. Suitable for high-end jewelry and watch packaging, as well as limited-edition wine gift sets, it enhances the sense of "luxury" through its shimmer and three-dimensionality.

Blind Embossing

Without adding ink or foil, the effect is created solely through the textured surface, making it suitable for minimalist styles. If the brand's style is environmentally conscious and leans towards tranquility and understated luxury, blind embossing can be used to create a high-end packaging box.

Combination Embossing

This process combines multiple techniques such as embossing, foil stamping, and printing to achieve rich layers and complex structures. For highly customized high-end wine packaging boxes and gift boxes, this technique can be recommended as an upgraded version.

Recommendations for Applying Embossing in DHPBOXES Packaging Box Projects

1. Define Brand Positioning and Visual Language

Before design, work with the client to define the brand's feel: classic retro? modern minimalist? Sparkling luxury? or understated elegance?

Based on the positioning, determine the embossing depth, placement, whether to use metallic foil, and whether to create a full-page or partial texture.

2. Material Selection: Thickness, Specialty Paper, Textured Paper

Embossing places high demands on paper: paper that is too thin or coated is prone to cracking. At DHPBOXES, we provide standard testing mechanisms based on client needs to ensure that the product is aesthetically pleasing while meeting usage standards.

DHPBOXES recommends that when selecting specialty paper for wine gift boxes and jewelry packaging boxes, materials with a thickness ≥300 g/m², long fibers, and resistance to cracking should be preferred.

3. Mold and Registration Precision Control

Custom embossing molds are costly, and once invested, they need to be used long-term to amortize the cost. Therefore, for clients with a unified brand visual identity (such as liquor brands and high-end jewelry brands), it is recommended to include embossing design as part of a long-term project to reduce per-item costs.

4. Coordination with Structure, Size, and Printing

When designing high-end packaging boxes (such as hinged lid boxes, double-door boxes, etc.), embossing should be coordinated with the box lid structure, opening and closing mechanism, and product display surface. It is best to place the embossing on the opening interface, inner tray surface, or prominent side to enhance the visual and tactile experience.Additionally, if the embossing position is close to printed text or metal foil, ensure mold registration accuracy to avoid misalignment or printing deviations.

5. Cost and Production Considerations

Embossing is a value-added process, with higher mold and setup costs. Custom metal molds, as well as heating and pressurizing, will increase initial investment costs.

Frequently Asked Questions

Q: Can embossing be used on recycled materials?

A: Yes. Choosing an embossing process that does not require metal foil or additional coatings can maintain the recyclability of the paper.

Q: Will embossing affect the smoothness of printed color blocks or laminated surfaces?

A: Possibly. If the paper is too thin or the coating is unsuitable, cracks, dents, or even lamination may occur in the embossed area. Therefore, suitable paper should be selected during the design phase, and rigorous testing should be conducted during the sampling phase.

Q: Is there a minimum mold cost or minimum order quantity requirement?

A: Due to mold customization, machine setup time, and manual operation, embossing processes usually have a high minimum order quantity. DHPBOXES can provide customers with an estimated quote and select a suitable solution based on their needs.

Q: Which packaging structures are suitable for embossing?

A: Almost all rigid boxes (such as hinged boxes, double-door boxes, and sliding boxes) can be embossed. It is especially recommended for "display surfaces" (such as the first view after opening), "surfaces with prominent brand logos", or "surfaces with high touch frequency" (such as the edge of the box lid and the drawer slide).

Conclusion:Through embossing, packaging boxes can convey a brand's deep sense of quality, meticulous craftsmanship, and unique positioning.

In the luxury packaging industry, quality is not only reflected in its aesthetic appeal but also in its tactile experience.

With over a decade of experience serving high-end European and American brands, DHPBOXES is ready to provide your brand with customized, environmentally friendly, and high-quality luxury packaging solutions.

Custom Apparel Boxes | Folding Magnetic Box with Ribbon | Custom Luxury Packaging Boxes

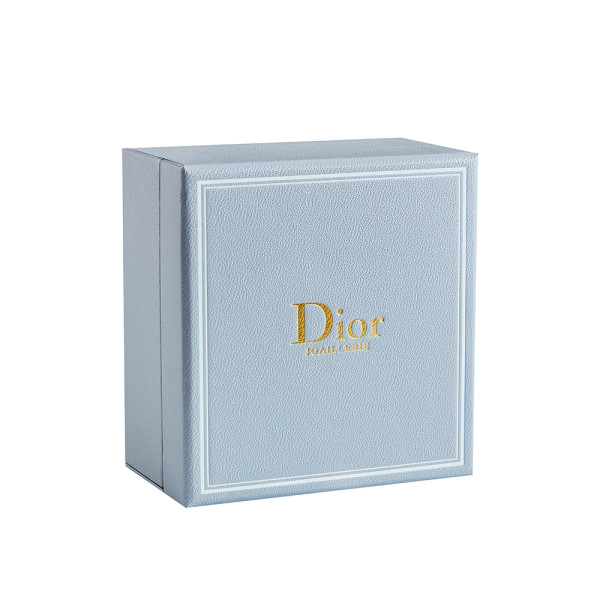

Custom Jewelry Boxes with Logo Wholesale | 2.5mm Thickness Rigid Cardboard | Light Blue Texture Paper Material

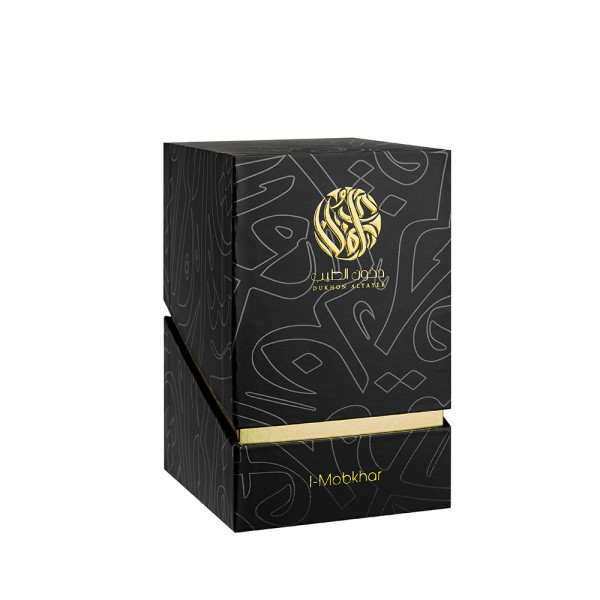

Rigid Perfume Bottle Box Packaging | Lid and Base Box with Neck Structure | Matte Black with Gold Foil Logo Design

Brandy Packaging Box for premium spirits | customizable, durable elegant design to elevate your brand presentation.