Gift Box Customization and Assembly Guide from Packaging Box Experts

This article briefly describes the importance of gift boxes in brand communication and user experience: how customized gift boxes can improve customer satisfaction and create a memorable unboxing experience. From design to assembly, packaging experts reveal the production process of customized gift boxes.

1. Basic Elements of Customized Gift Boxes: Structure, Materials, and Craftsmanship

Design considerations fall into three categories: structure (the function of the box), materials (its constituent materials), and printing/surface treatment (its appearance and feel).

Common gift boxes:

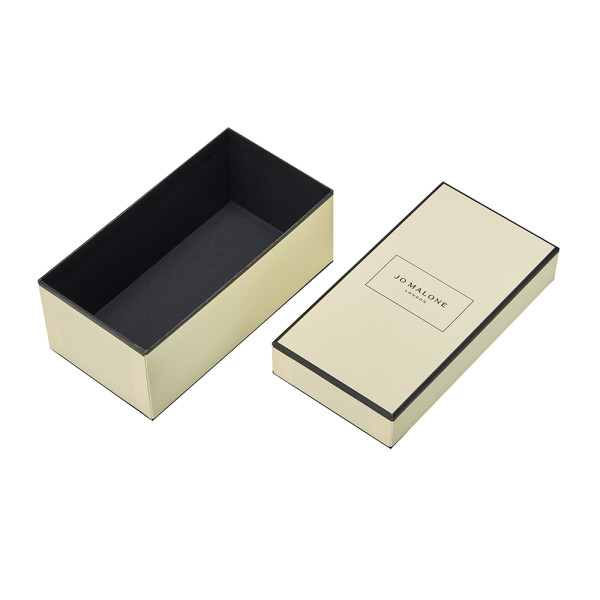

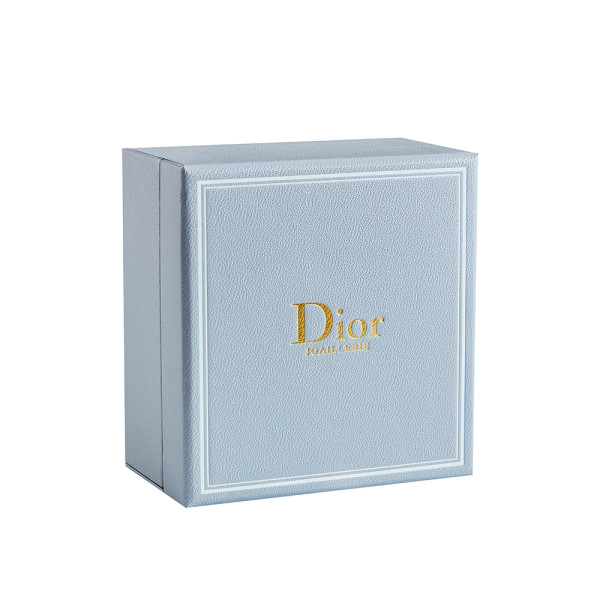

A. Two-piece rigid packaging box (lid + base): High-end feel, ideal for storing luxury perfumes, jewelry, and cosmetics. Reusable.

B. Folding cardboard box: Economical, easy to lay flat for transport, suitable for single-item retail display.

C. Corrugated cardboard gift box: Provides both packaging and transport protection, ideal for subscription boxes or fragile items.

D. Display box: Features windows or die-cut designs to maintain brand image while showcasing products.

Custom Vintage Christmas Candy Boxes | Uses Environmentally Friendly and Biodegradable Corrugated Paper Materials

Custom Shipping Boxes For Clothing From DHP Boxes | Eco Friendly Packaging For Baby Clothes | With Transparent PVC Window

Custom Perfume Gift Box Factory | CMYK Printing Design with Matte Lamination | Beige Texture Paper Wrapped Gray Board Material

Elegant CMYK Printing Design with Hot Foil Stamping Embossed Logo Use for Garments, Apparel, Shoes, Hat, and Handbag Packaging.

Materials

A. SBS Cardboard: Bright white, excellent print quality – ideal for the luxury and cosmetics industries.

B. Hardboard: Thicker, used for making assembly boxes.

C. Corrugated Cardboard: Used to improve transport strength (single-layer and double-layer corrugated board available upon request).

D. Recycled Paper and Kraft Paper: For an environmentally friendly positioning.

Printing and Processes

(1) High-volume printing utilizes offset and flexographic printing, with CMYK/PMS spot colors ensuring brand accuracy.

(2) Low-volume printing or variable data digital printing.

Strategically combine finishes—e.g., matte lamination for the body with selective gloss varnish or foil stamping on the logo—to create contrast and elevate perceived value. Check out How to Make Your Own Box Packaging with Munufacturer or Supplier?

A.Lamination (matte, gloss) protects the print and alters the feel.

B.Varnish (spot UV, water-based) selectively adds gloss.

C.Hot stamping, embossing/gravure: a mark of high-end luxury.

D.Windowed designs and ribbon closures add drama to the unboxing experience.

2. How to Design Custom Gift Boxes that Align with Brand Image

When using customized gift boxes with a logo, brands shouldn't focus solely on the appearance. The unboxing process itself is a brand experience: peeling back layers, feeling the texture, and discovering the carefully designed lining.

First, define the core message—what should the recipient feel? Then, design a layered presentation: outer packaging, inner box, product display area, and a handwritten note or brochure. Personalization is extensive, ranging from printing names on the box to scanning QR codes to watch welcome videos. For corporate gifts, customized corporate gift boxes using company colors, embossed logos, and personalized greeting cards significantly enhance the perceived value of the gift.

Maintaining consistency in brand marketing is crucial. Keep brand fonts, color codes, and images consistent across all packaging elements to enhance brand recognition.

Below are brand gift box references from DHPBOXES, revealing how experts embody brand identity in gift boxes.

High quality personalized watch set box for brand, Premium gray board, velvet interior and closure.

Perfume Gift Box Supplier | 120gsm Coated White Fancy Paper Mount Gray Board Material | White EVA Foam Insert Wrap Gold Paper

China Perfume Gift Box Manufacturers | Matte Black Rigid Cardboard Material | Elegant Design with Jo Malone Brand

Brandy Packaging Box for premium spirits | customizable, durable elegant design to elevate your brand presentation.

3. Size, Die-cut Lines, and Templates: Planning Your Folding Gift Box Templates

A. First, provide accurate product dimensions, taking into account the size of the protective cushioning layer (typically a 5-15 mm gap).

B. Next, consider the dimensions of internal dividers or trays for storing multiple products, serving to protect the products and prevent them from shifting.

C. When designing die-cut lines, clearly mark crease lines, adhesive labels, and bleed margins (typically a 3 mm bleed).

Unsure what product suits your project the best?

4.Cost, MOQ, and Lead Times (what to expect)

1. Costs depend on size, materials, printing, and surface treatment.

Hardboard boxes and heavily embossed boxes cost more than regular folding boxes. Minimum Order Quantity (MOQ) varies by process: small orders for digital printing may require only a few hundred pieces, while traditional offset die-cutting projects typically require thousands to reach an economical price point.

2. Lead Time: Prototyping takes 5-15 days, and mass production takes 2-6 weeks, depending on complexity and order size. Please plan ahead to account for seasonal peaks (such as the fourth-quarter holidays), when factory and shipping capacity will be limited.

DHPBOXES offers flexible MOQ options and clear lead time estimates to customers in the US, Europe, and Australia—we recommend contacting our sales team as early as possible during the planning phase (for a quote).

5.Frequently asked questions (FAQ)

Question 1: What's the difference between folding gift boxes and rigid gift boxes?

Folding gift boxes fold flat, are economical, and suitable for bulk packaging; rigid gift boxes have a premium feel and sturdy structure, but are more expensive and take up more space.

Question 2: Can I add my logo to any type of box?

Yes. Logos can be printed, hot stamped, embossed, or stickered. The specific choice depends on your budget and desired effect.

Question 3: How can I ensure my boxes can withstand international shipping?

Use an outer corrugated cardboard box, add a protective liner, and conduct packaging tests according to the complete shipping process, including simulating rough handling.

Question 4: What is a reasonable minimum order quantity (MOQ)?

DHPBOXES'MOQ varies depending on the situation: the MOQ for digital printing may be very small (a few hundred pieces), while the MOQ for offset printing, die-cutting, and rigid gift box production may reach several thousand pieces. It is recommended to negotiate with the supplier for staggered production or mixed SKU production to reduce inventory pressure.

6.Packaging Drives Sales: How DHPBOXES Packaging Helps Sell

Gift box production is both a craft and a science. From choosing the right structure and materials to designing a branded unboxing process and planning logistics, every decision impacts cost, consumer perception, and product performance.

For companies targeting the US, European, and Australian markets, the right partner can mitigate risk: precise die-cutting lines, material recommendations, quality control, sustainability solutions, and optimized production processes.

DHPBOXES specializes in providing custom rigid boxes, folding cartons, and corrugated cardboard solutions for a wide range of industries, including jewelry, fragrances, cosmetics, food, cigarettes, and corporate gifts. We offer design support, prototyping, and end-to-end production services, with highly competitive minimum order quantities and extensive global shipping experience.

Recommended for you

Custom Christmas Present Boxes with Lids | Christmas Festive Gift Packaging Boxes for Chocolate | Good Gift Box Options

Custom Jewelry Boxes with Logo Wholesale | 2.5mm Thickness Rigid Cardboard | Light Blue Texture Paper Material

Custom Gift Boxes Packing for Chocolates Candy Dessert and Ect | Gold Blister Tray Insert

Double Sides Open Rigid Cardboard Material Whisky Presentation Box | Eco-friendly Paper Card Insert