Foldable Gift Boxes vs Rigid Gift Boxes: Which Is Better?

In premium packaging, two styles dominate—foldable gift boxes and rigid gift boxes. Both deliver an elegant look and reliable protection, but they differ in storage, logistics, and the unboxing experience. At DHP Boxes, we engineer and manufacture both, helping global brands balance cost-efficiency with luxury presentation.

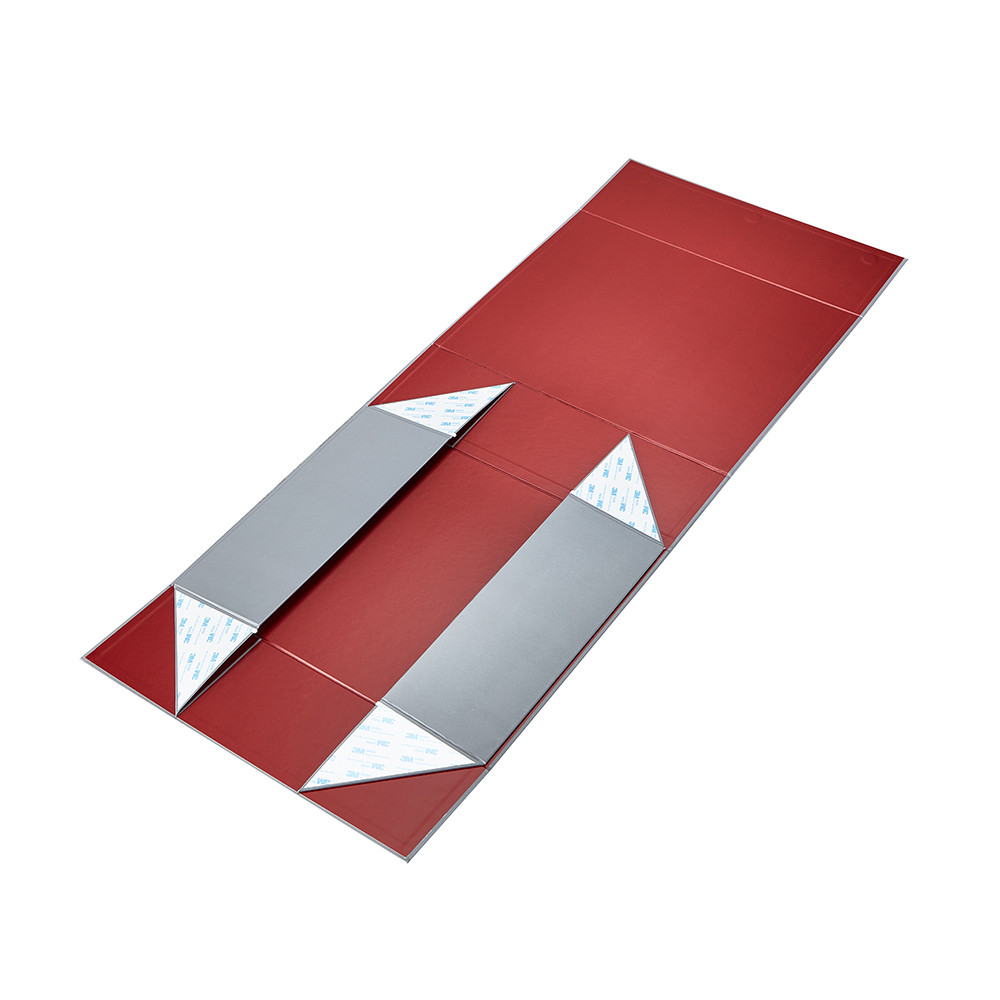

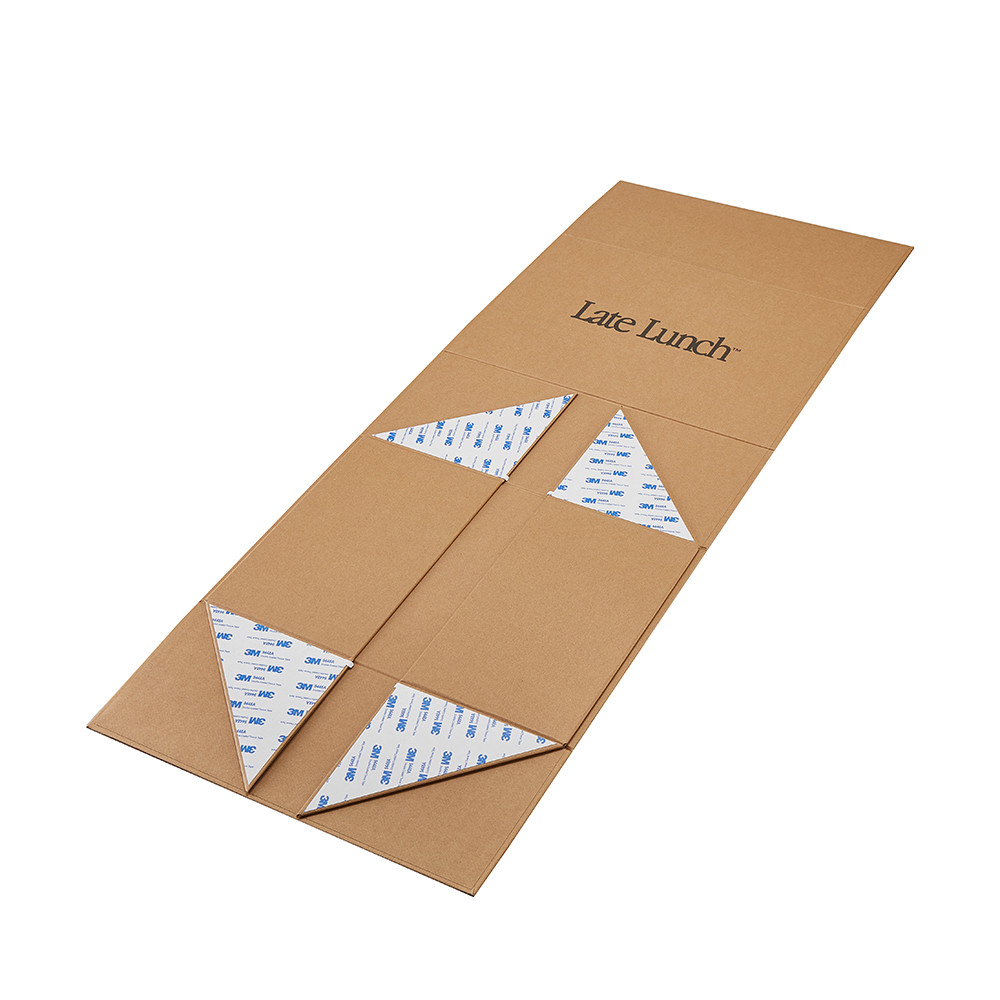

1) What Are Foldable Gift Boxes?

Foldable gift boxes—also called collapsible or flat-packed boxes—are designed to assemble in seconds and fold flat when not in use, saving up to ~80% of storage and freight volume (actual savings vary by size and packing method). Using precision die-cutting, strong magnets, and reinforced edges, foldable boxes lock into a stable, rigid shape after assembly.

Space-saving: significant reductions in warehousing and international freight

Premium closures: magnetic, ribbon, or tuck-in options

Durable boards: grayboard with art paper, kraft, or specialty papers

High-end finishes: foil stamping, emboss/deboss, spot UV, soft-touch

Eco-forward choices: recycled/FSC-certified papers and water-based coatings

Texture Paper Material

Art Paper Material

Brown Kraft Paper Material

2) What Are Rigid Gift Boxes?

Rigid gift boxes (also called set-up boxes) arrive pre-assembled and non-collapsible. They deliver a luxury hand-feel and a dramatic unboxing experience for products like jewelry, cosmetics, confections, and premium beverages. The trade-off: higher storage volume and typically higher shipping costs.

Luxury presentation right out of the carton

Excellent stiffness for fragile or premium products

Versatile structures with custom inserts, windows, and compartments

Ideal for limited editions and high-value gifting

3) Foldable vs Rigid: Head-to-Head Comparison

Feature | Foldable Gift Boxes | Rigid Gift Boxes |

Structure | Collapsible (flat-packed) | Pre-assembled (non-collapsible) |

Storage Efficiency | Up to ~80% volume reduction | Higher volume / more warehouse space |

Shipping Cost | Lower due to flat packing | Higher due to dimensional weight |

| Setup / Handling | Quick assembly on site | Ready to use out of the carton |

| Durability | Strong after assembly | Very strong and rigid |

| Cost Profile | Cost-efficient for bulk & exports | Premium cost; top-tier feel |

| Best For | E-commerce, seasonal, retail gift sets | Jewelry, cosmetics, luxury collections |

4) Which One Should You Choose?

Pick Foldable Gift Boxes If You Need

Lower freight and warehousing costs

Scalable seasonal packaging and global shipping

Premium look with magnetic or ribbon closures

Eco-forward materials and reduced packing volume

Choose Rigid Gift Boxes When You Want

Maximal stiffness and “wow” unboxing

Showpiece packaging for premium SKUs

Complex inserts, windows, and multi-layer structures

Immediate shelf-ready presentation

For many brands, a hybrid approach works best: foldable rigid boxes combine flat-pack efficiency with rigid-box strength—ideal when you need both sustainability and premium feel.

5) Why DHP Boxes?

With 20+ years of manufacturing, DHP Boxes provides OEM/ODM packaging for luxury brands across beauty, wine & spirits, confectionery, and fashion. We combine engineering precision with handcrafted finishing to deliver packaging that protects, inspires, and converts.

In-house design & production: CAD dielines, structural prototyping, mass production

Premium closures & inserts: magnetic lids, EVA/velvet/foam/pulp inserts

Sustainability: FSC-certified papers and water-based inks/varnishes

Global logistics: export-ready packing, carton optimization, reliable lead times

Trusted by international brands with consistent QC and after-sales support

6) Conclusion

Both formats have a place in modern luxury packaging. If you want efficiency, sustainability, and brandable elegance, start with foldable gift boxes. For hero SKUs and immersive unboxing, rigid gift boxes remain the gold standard. DHP Boxes helps you choose—and custom-engineer—the right solution for every product line.

Ready to Upgrade Your Packaging?

Get a custom quote, dieline, and prototype from our engineering team.